3. Repair a loose laser unit on the Hotech ACT

I wanted to align the lower left laser as well, it's off by only a tiny bit.

When I started the collimation of this unit I saw that the laser dot moved

several centimeters on the target when I just inserted the hex key in one of

the grub screws. The red colored aluminium cylinder was loose. After a mail to

David from Hotech I received the instructions on how to fix this; unscrew the

two silver set screws on the back of the laser collimator at 9 and 3 O'clock

position. This will release the front target panel and you will find the three

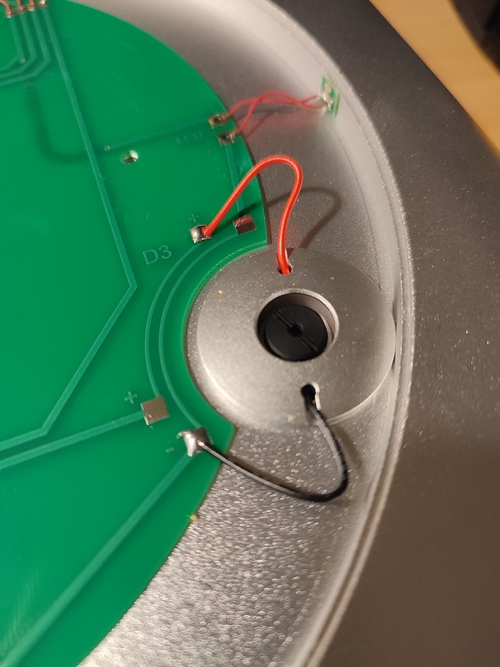

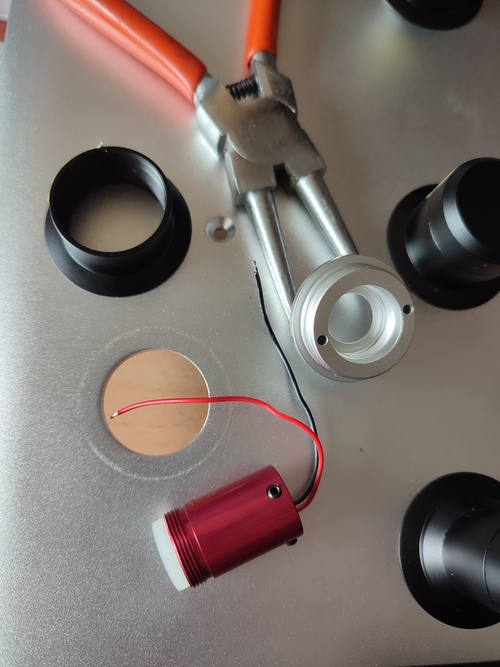

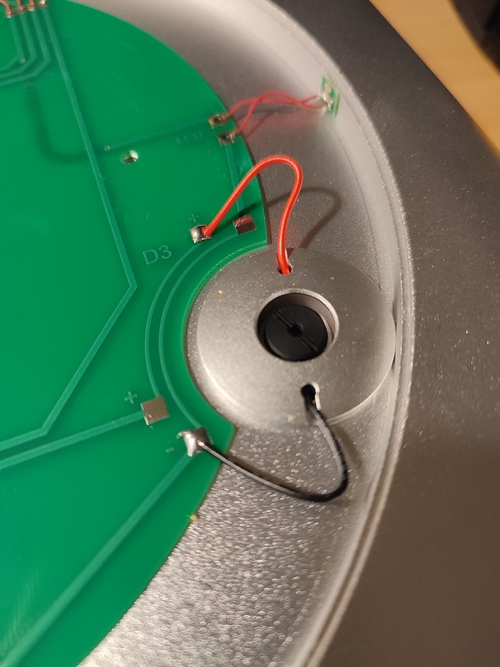

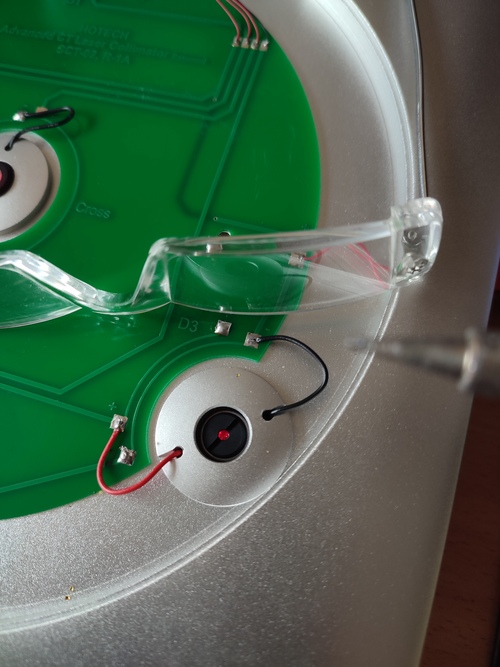

laser silver caps at 12, 8, and 4 O'clock position. The front of the laser with

the silver cap looks like this :

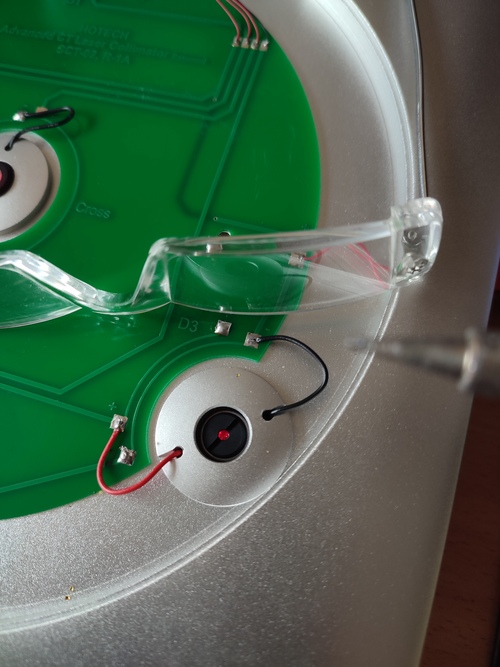

The red and black wires pass from the PCB board to the back end of the laser

unit through the holes with which the silver cap is screwed onto the black

safety cylinder at the back end of the unit.

Be very careful with these wires. They break easily at the solder

points, both on the PCB side as well as on the laser unit backend side.

I think the easiest way to tighten the silver cap/black safety cylinder

combination is to hold the silver cap in place with a tool as you do not want

to adjust the place of the wiring while screwing the black safety cylinder at

the back side tight. This way you do not have to disassemble the whole unit.

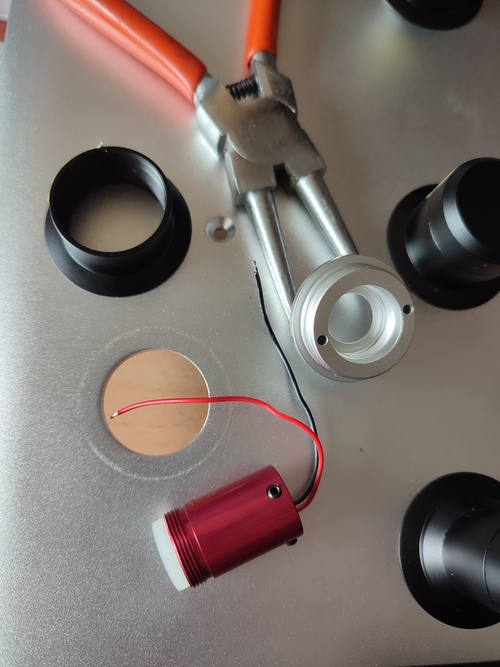

This is not what I did as I wanted to see how the entire thing was held

together. Totally unnecessary of course but I'm curious and already got this

far in. So I disassembled a whole unit. First desolder the wires from the PCB,

and get them to the other side. Then use a tool to unscrew the unit.

The red cylinder holds the laser units with two nylon rings at the front that

allow for some tilt adjustment at the back with the grub screws. Nice system.

Next I put it all back together and as you can see the laser unit still works.

At this point both wires broke off at the laser unit side. But they're easy to

solder back in place if you have a soldering iron with a fine tip. After

assembly the wires were better aligned for the other solder point so I happily

made use of them. Great PCB design.

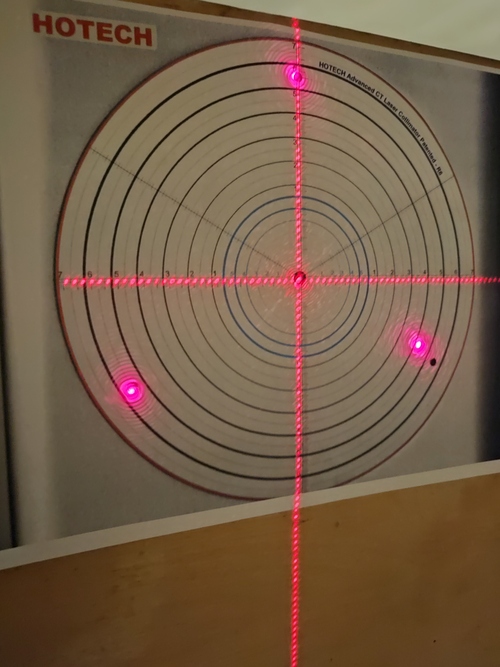

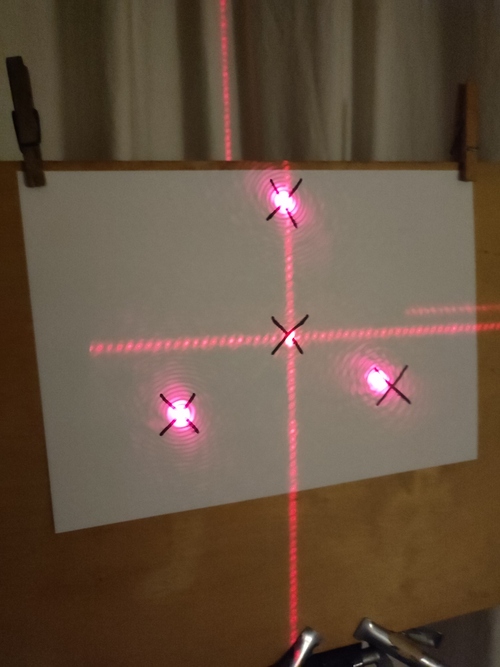

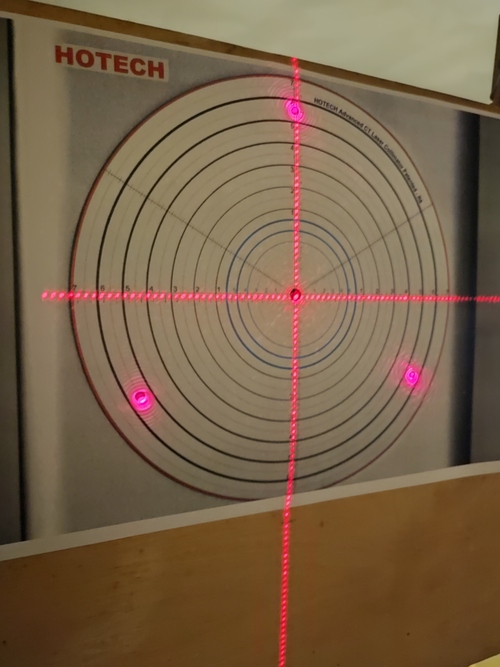

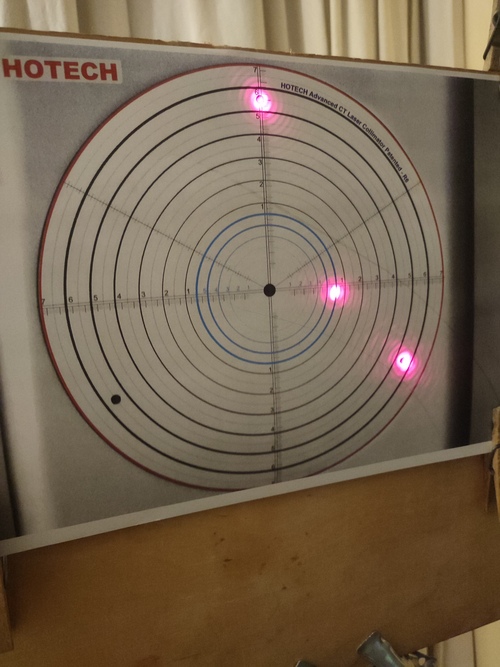

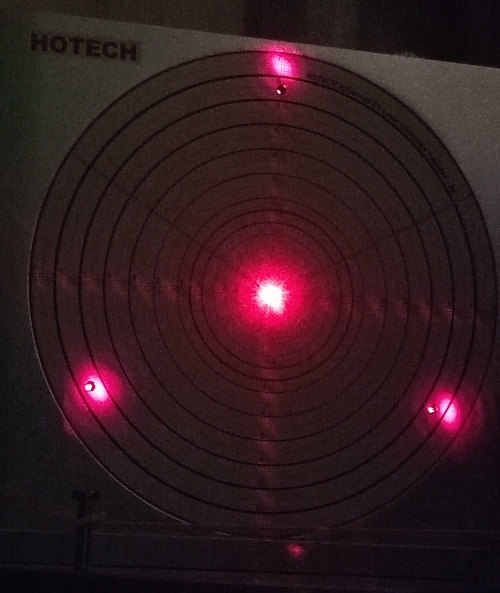

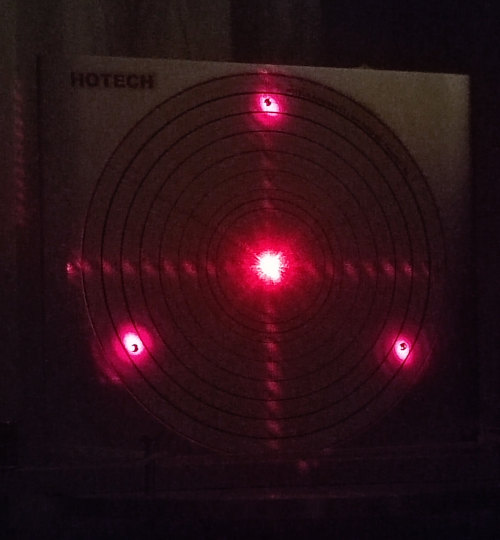

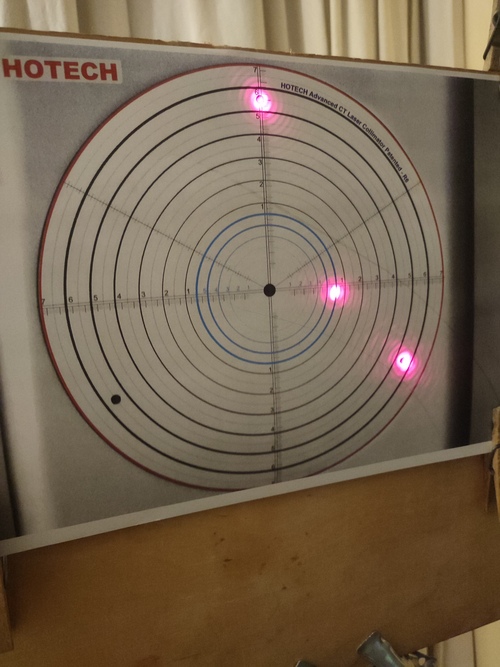

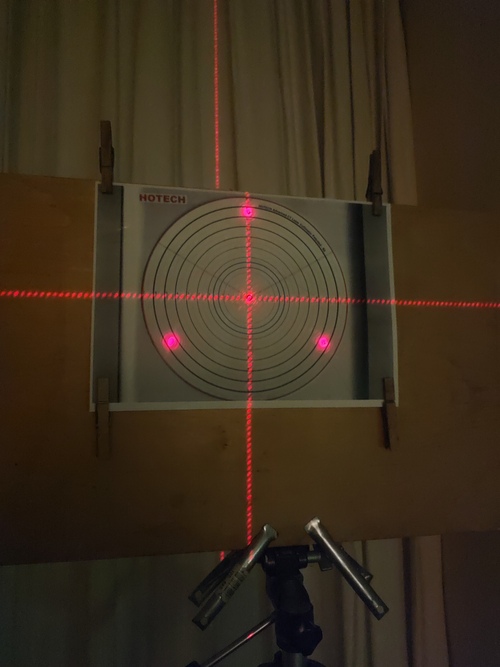

Next is using the grub screws to properly adjust the laser, from :

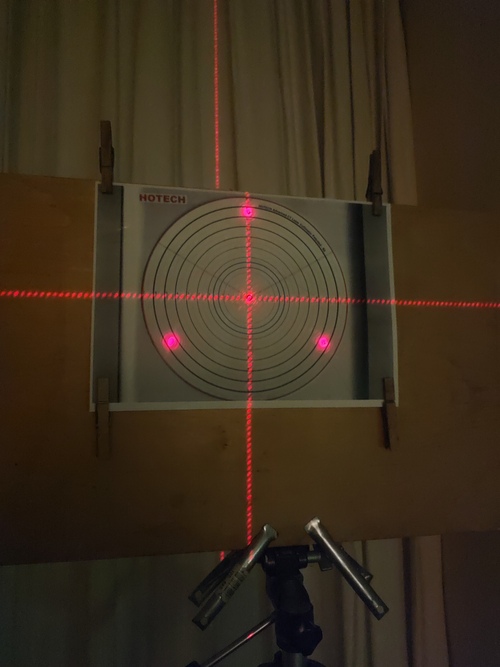

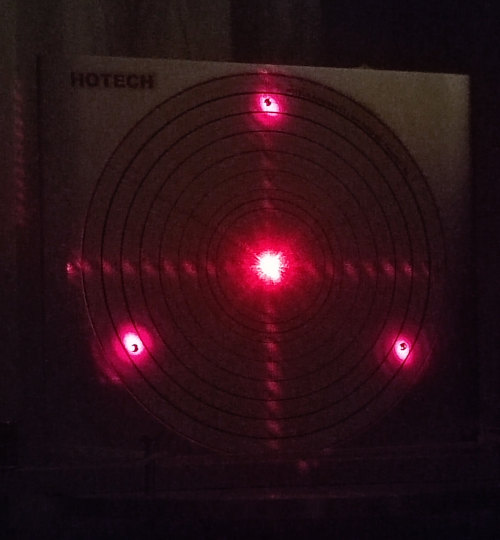

To the perfect-to-me result :

I think this is an awesome device. Thanks Hotech for making it, and making it

serviceable.

4. Further tune the Hotech ACT at 16 meters using a mirror

After getting quite good but still not optimal results on collimating an RC I

decided to revisit the collimation of the collimator itself. And for that I

needed more sensitivity, meaning an even greater distance to the target. The

earlier effort with a paper photocopy of the ACT at a larger distance was not

easily possible in my house, and I also did not want to again repeatedly walk

between the source and the target to see the result of a very tiny adjustment

of a grub screw. So I used a mirror that was also reflecting on the back side

(so that the beam does not pass any refracting glass) that I had still lying

around for another project and doubled the beam distance from 8.1 to 16.2

meters.

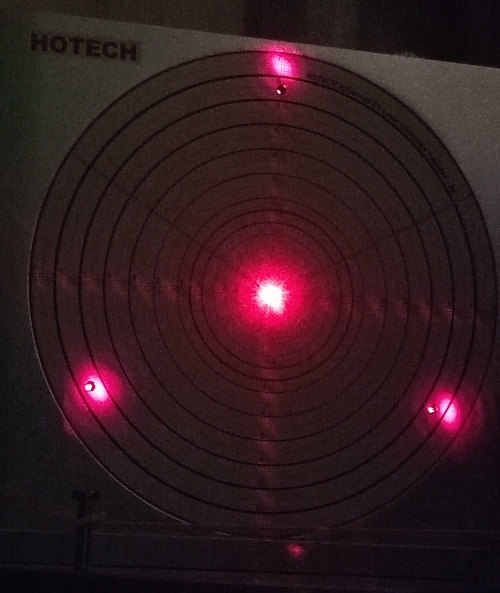

This worked really well. While the paper target at 8 meters showed all was fine

the result at 16 meters was quite different :

And the adjustments were so much easier to do, no more walking to the target to

see what the adjustment result was but instant feedback right at the source.

Why did I not think of this before ? So much easier and more sensitive.

At 16 meters distance the dotted crosshairs are becoming small diagonal lines

and the laser dots become big oval shaped blobs. I was happy with the following

result :

Last page update :

2023-08-30T21:02Z

-- Hans Lambermont